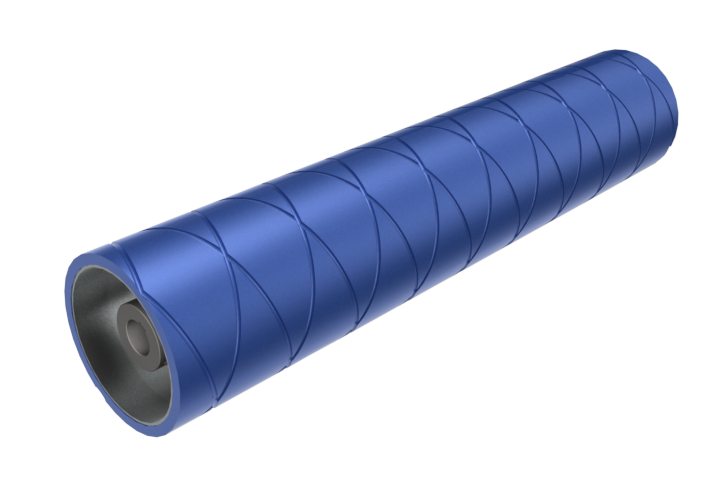

TuffCote® Urethane Pulley Lagging & Roller Coatings

When compared to rubber, Tuffcote® urethane pulley lagging (Durathane) offers superior abrasion resistance, vastly superior chemical resistance, and is not hygroscopic. Its water absorption rate is below 1%. Unlike pouring urethane into a mold, we use a form following process. The absence of a mold reduces cost, improves lead time, and simplifies prototyping and the production of short-run quantities. Since our process is continuous flow – we can offer shorter lead times, superior throughput, and lower costs. We can apply Tuffcote® urethane pulley lagging to irregular shapes such as tapered pulleys and conserve on the use of costly materials.

Request Product InformationResources & Downloads

Design & Engineering Features

The lack of molds and the proprietary chemistry and mixing process we use enables us to lag and ship within 24 hours in an emergency. Our urethane roller lagging comes in a variety of colors and is available in 75, 85, and 95 durometer. We can supply urethane pulleys and urethane rollers in an as molded, machined, or ground surface finish. Our urethane lagging is not limited to rollers and pulleys, variants of our base material have been used on applications from lining hydro-cyclone tubes to providing a base over shafts for subsequent machining operations.

High Efficiency

TuffCote® urethane lagging (Durathane) and pulley and roller coatings from Bryant Products shattered the price barrier that stood between system engineers and the many superior qualities of urethane lagging and coatings.

Our process is so time and materials efficient that we are able to offer urethane lagging at pricing competitive, if not better, than lower grades of rubber lagging compounds. We are also specialize in urethane lagging repair on existing components.