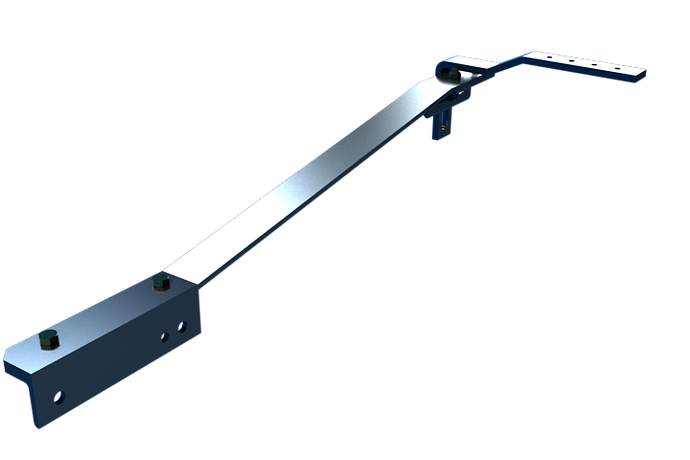

Airform Metal Forming for Conveyor System Components

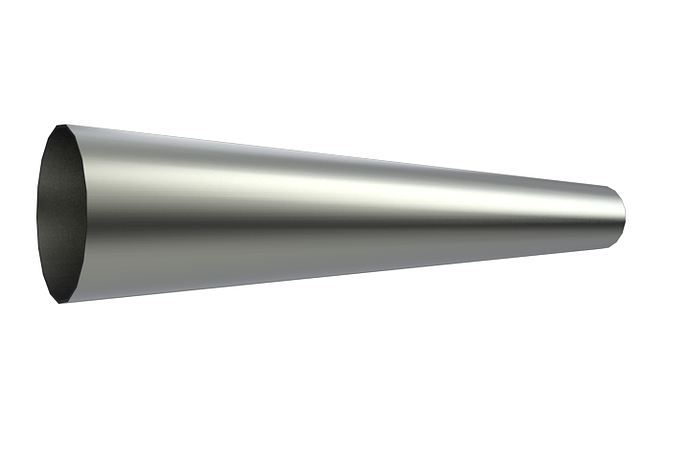

Many years ago, the conveyor industry asked us to solve the problems of excessive run-out, poor quality, long lead times and indifferent service they faced when buying tapered rollers from manufacturers using rotary swaging, mandrel spinning, and hydro-forming. They wanted to avoid tooling costs. They wanted greater design flexibility. They wanted shorter lead-time and lower costs. Companies producing belt curves wanted a process capable of producing one-piece tapers in diameters of 5″ and above.

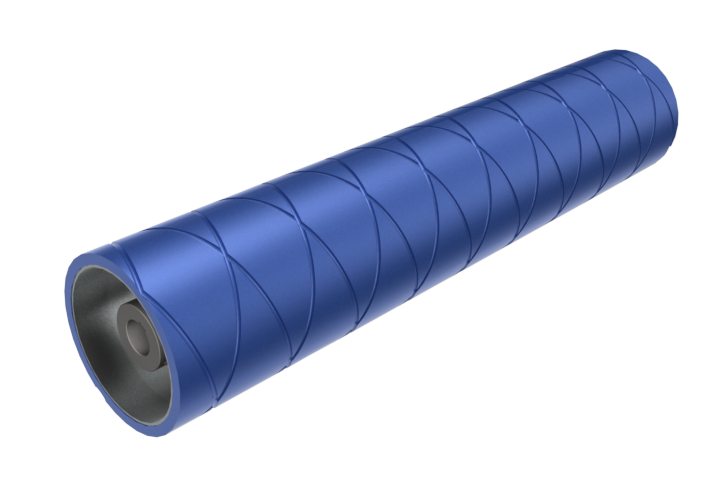

We gave them AirForm® – the revolutionary forming technology invented by Bryant Products. AirForm® provided all that the conveyor industry asked for and then some: no hard tooling, the ability to produce any taper angle, reduced costs and set-up charges, and far greater precision and quality than anyone thought possible. We can produce tapers, concave, convex forms compound tapers, waveforms and cylindrical shapes with single or multiple crowns or grooves. AirForm® offers TIRs as low as .010 and is capable of producing tapers with major diameters of 5″, 6″, 7″, 8″ and 9″ and lengths up to 82″ using tubing with a wall thickness as thick as .250″.

Economical & Versatile

What makes this process so extraordinary, is that AirForm® does not require any hard tooling. It makes long and short run production and prototype lots economically feasible. Designers now have the freedom to choose what they need rather than what is or is not tooled. We can produce true tapers and fixed diameters for roller turns with equal ease and match any turn radius required. Our Airform® belt pulleys are now the platinum standard for airline baggage handling systems and offer CNC precision in a lighter wall formed tube.

Since its introduction in 1998, we have produced many other complex shapes for a variety of industrial applications. We have replaced castings for hydrocyclone tubes and industrial air-horns, we have replaced hydro-formed tubes in structural applications requiring greater design flexibility and produced compound taper and wave forms for decorative furniture legs and braces, just to mention a few. We have produced shapes in carbon steel, stainless and aluminum.

While even Bryant’s engineers are limited by the laws of physics, AirForm® comes closer to, “Imagine it and we will make it,” than any tube forming process on the planet.