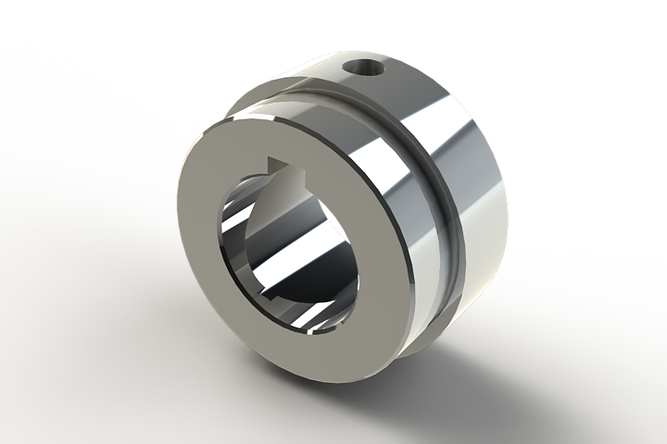

CNC Machined Precision Components

Bryant Products features a large well-equipped, advanced CNC department. Our equipment is of the latest technologies, offering the highest levels of precision, programming flexibility, repeatable quality, and surface finishes. Like our many lines of conveyor components, our CNC department is fully supported by a talented and very experienced engineering department.

Our Capabilities include designing and manufacturing, quality check points including first article certification and PPAP’s. We also provide secondary operations that include: Heat Treating, Plating, Tumbling, and Welding.

All of our primary CNC operators and QC personnel have over 12 years of experience. We also offer dynamic balancing up to an H6 tolerance. Many of our lathes are bar fed and have live tooling stations providing our clients with high precision and repeatability at efficient pricing.

Lathes

Slant and flat bed lathes, bar feed capabilities for reduced costs, live tooling which permits milling and drilling operations with secondary machining and set-ups – diameters to 14″ with face widths to 60″ – sub .001″ TIR capabilities with shaft tolerances down to .0006″ – finishes to 16 RMS.

Vertical Machining Centers

We have a variety of single and dual station CNC machining centers. Our dual station centers allow gang-fixturing of higher volume parts or the simultaneous run and load of more complex parts.

All of our CNC equipment is augmented by a number of late model manual machines.

Variety of Materials

We have experience working with low carbon steels, specialty alloy high-strength steels, both 300 and 400 stainless steels, aluminum and various grades of thermoplastic.

- Carbon steel

- Stainless steel

- Aluminum

- Plastics

- Steel alloy (4140, 1144, 8620, others available)

- Brass and copper alloys

- Turned, ground, and polished (TGP) stocks